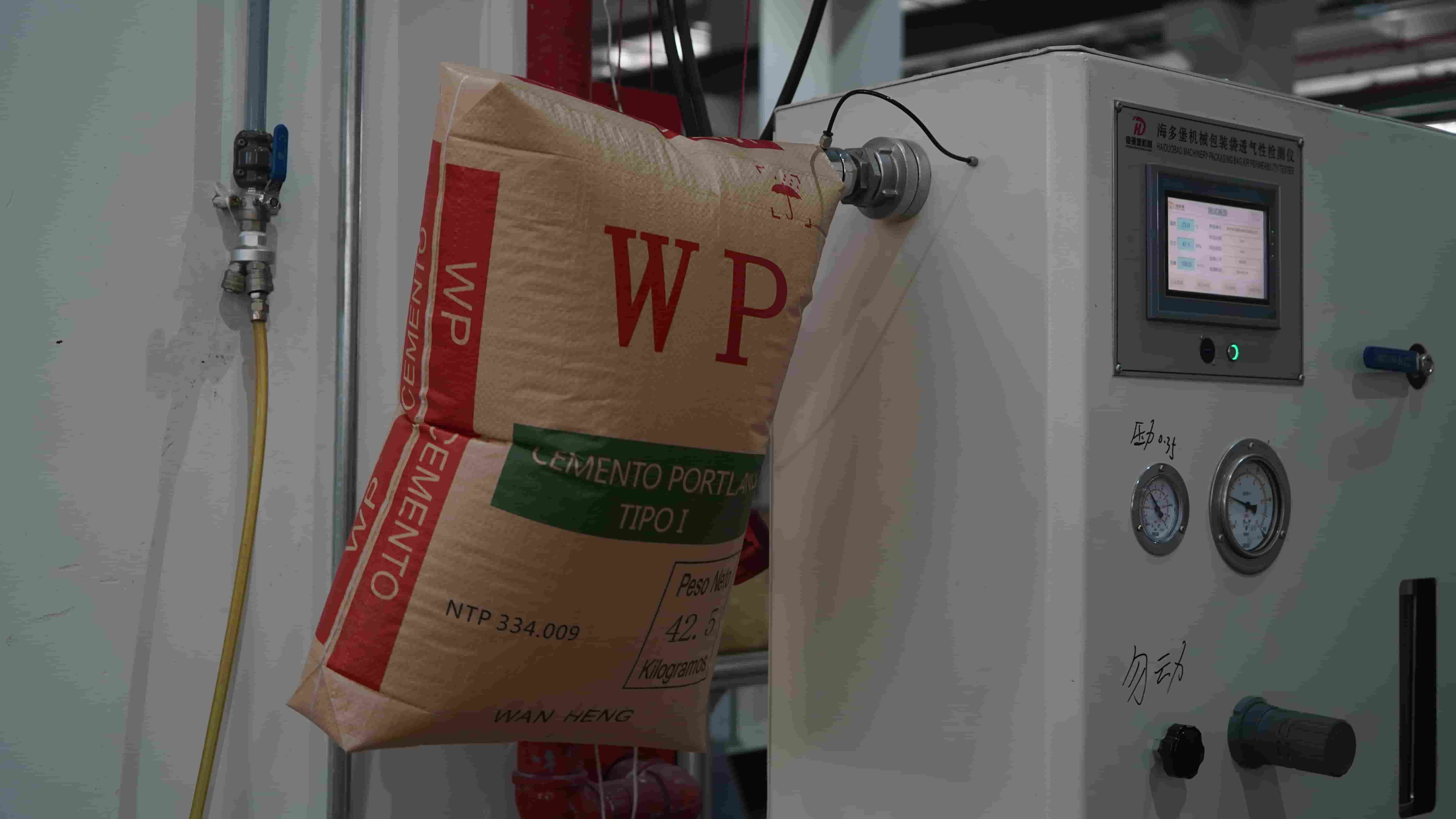

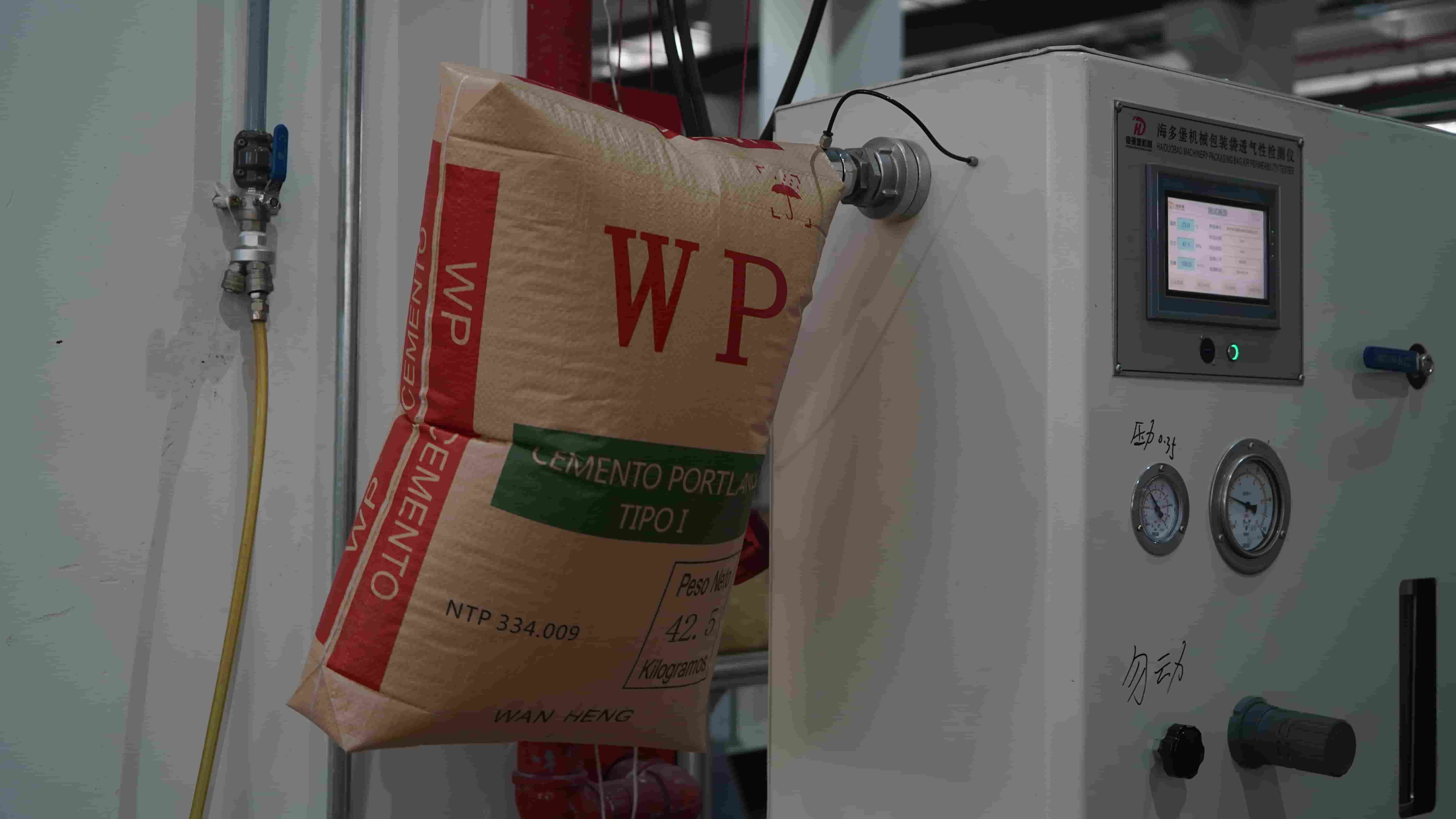

Тестер воздушного потока для подключения к клапанам

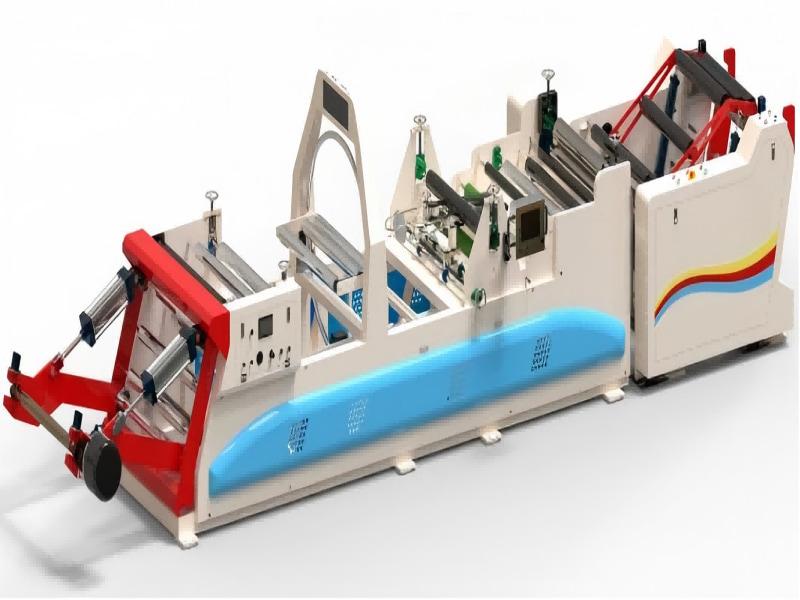

Gachn Group Woven Bag Tester Tester GC-346-4-это оборудование для тестирования с высоким разрешением, предназначенное для промышленности упаковочных пакетов, интегрируя проницаемость воздуха, сопротивление под давлением и функции тестирования потока. Тестер на скамейке воздуха поддерживает комплексную оценку производительности различных упаковочных материалов, таких как мешки с нагреванием клапанов, мешки для шва клапанов и пакеты с бумажными клапанами. Благодаря интеллектуальной эксплуатации и обратной связи данных в реальном времени, это помогает предприятиям оптимизировать производственные процессы, обеспечить качество продукции и соответствовать международным стандартам, таким как GB/T.

Основные преимущества

Многофункциональный режим обнаружения

Постоянное обнаружение давления: точно контролировать диапазон давления (0-100 кПа, точность 0,01 кПа), проверьте воздушную проницаемость и скорость вентилятора упаковочных пакетов.

Постоянное обнаружение скорости: стабилизируйте скорость вентилятора (0-2800R/мин) и проанализируйте поток (0-220 м³/ч) и значение давления в режиме реального времени.

Обнаружение прочности: проверьте диапазон прочности таких процессов, как тепловое уплотнение, склеивание и швы, чтобы обеспечить долговечность упаковки.

Интеллектуальный опыт работы

Операция по одному касанию: оснащена 7-дюймовым сенсорным экраном, отображением скорости, потока, давления и других данных в реальном времени, интуитивно понятным представлением кривых тестовых кривых и результатов.

Несколько параметров хранения: поддерживает 30 наборов предварительных наборов параметров заготовки, быстро переключается на различные требования к тестированию продукта и повышает эффективность.

Удобное управление данными: отчет о тестировании может быть экспортирован в USB -накопитель (формат Excel), а исторические данные сохраняются в течение 90 дней для легкой отслеживаемости и анализа.

Безопасный и надежный дизайн

Механизм двойной защиты: механическая и электрическая безопасность конструкции блокировки блокировки, оснащенная защитой доступа и кнопкой аварийной остановки для обеспечения безопасной работы.

Строгие рабочие характеристики: поддерживает процедуры блокировки/теги, чтобы гарантировать, что оборудование будет включено во время технического обслуживания, чтобы избежать неожиданных рисков.

Адаптируемость окружающей среды: широкий вход напряжения (220 В ± 10%), стабильное давление источника газа (0,5-0,7 МПа), адаптируемое к сложным условиям труда.

Технические параметры с первого взгляда

| Элемент | Параметры |

| Напряжение питания | 220 В ± 10% 50/60 Гц |

| Рейтинг власти | 3,0 кВт |

| Давление источника воздуха | 0,5-0,7 МПа |

| Скорость вентилятора | 0-2800R/мин |

| Диапазон обнаружения потока | 0-220 м³/ч (точность 0,1 м³/ч) |

| Постоянный диапазон давления | 0-100 кПа (точность 0,01 кпа) |

| Диапазон давления прочности | 0-1mpa (точность 0,1 кпа) |

| Размер оборудования | 1100 мм × 800 мм × 1320 мм |

Операция

Однопультный старт, эффективное обнаружение

Выберите тестовый режим (постоянное давление/постоянную скорость/интенсивность) через сенсорный экран, запустите тестер измерения массового потока воздуха после установки параметров и автоматически завершите весь процесс инфляции, обнаружения и суждения данных.

Тревога в режиме реального времени для аномальных данных (приглашение к зуммеру + экрана), чтобы обеспечить своевременную работу проблем.

Гибкая конфигурация параметров

Пользователи могут настроить пороговые значения давления, потока и скорости, чтобы адаптироваться к различным стандартам обнаружения.

Поддерживать функцию блокировки пароля, чтобы предотвратить несанкционированную модификацию параметров и обеспечить надежность данных.

Тест цикла давления

Моделируйте фактические сценарии использования, установите количество циклов (по умолчанию в 2 раза) и значение давления (по умолчанию 120 кПа) для проверки долгосрочного сопротивления давления пакетного мешка.

Безопасность и техническое обслуживание

Необходимо прочитать перед работой: тестовая машина воздушного потока должна быть помещена в сухой и вентилируемой среде, вдали от легковоспламеняющихся материалов; Держите его на уровне во время транспортировки, чтобы избежать опрокидывания.

Профессиональное обслуживание: только сертифицированный персонал разрешается осматривать и ремонтировать. Перед техническим обслуживанием источник питания должен быть отключен, а заглушка должна быть отключена, и необходимо использовать изоляционные инструменты.

Регулярная калибровка: рекомендуется проверить точность датчика и герметизацию воздушного пути каждый квартал, чтобы обеспечить точность результатов испытаний.

Применимые сценарии

Производители упаковки: входящее осмотр сырья и готовый контроль качества.

Агентства по инспекции качества: выполните GB/T, ISO и другие стандартные сертификационные тесты.

НИОКР Лаборатории: Новое исследование проницаемости материала, поддержка данных оптимизации процесса.

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ