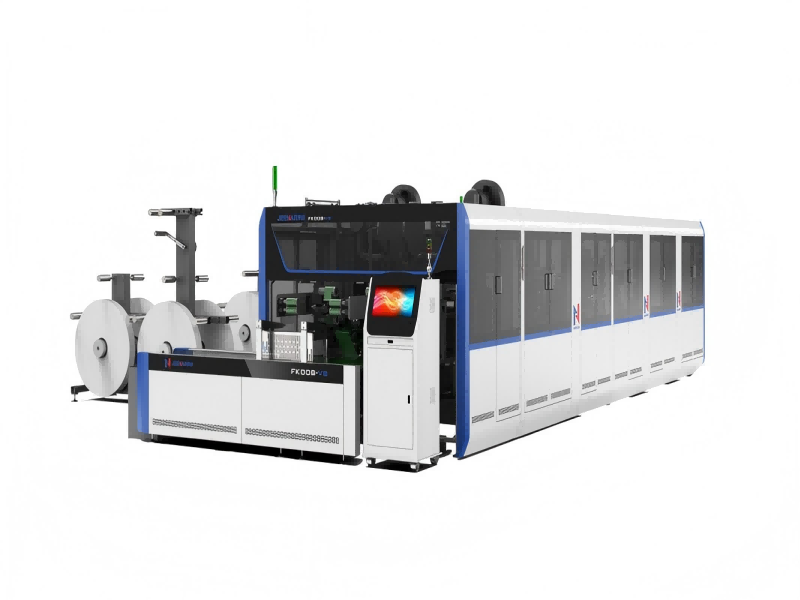

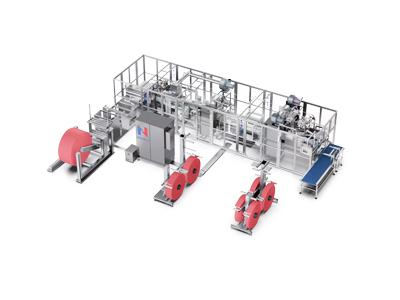

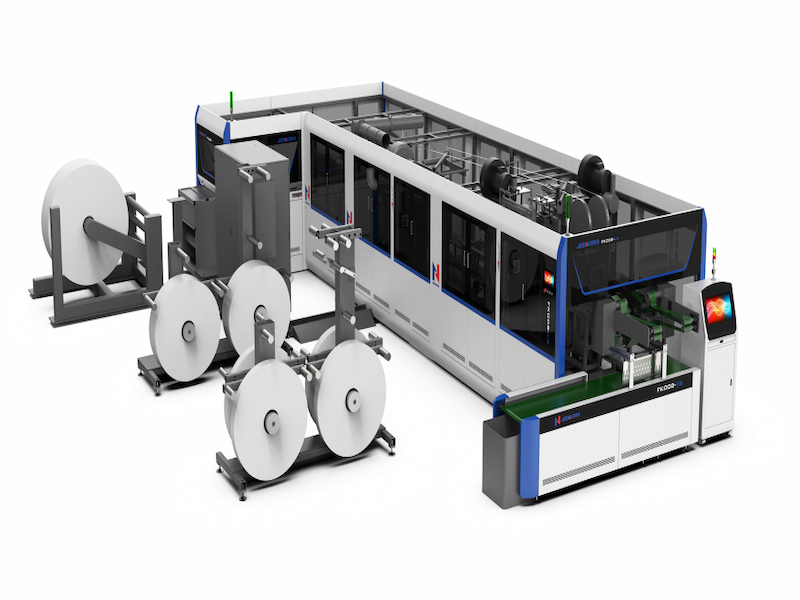

Автоматическая стенка сплетенного блок -мешка для сумки для AdStar

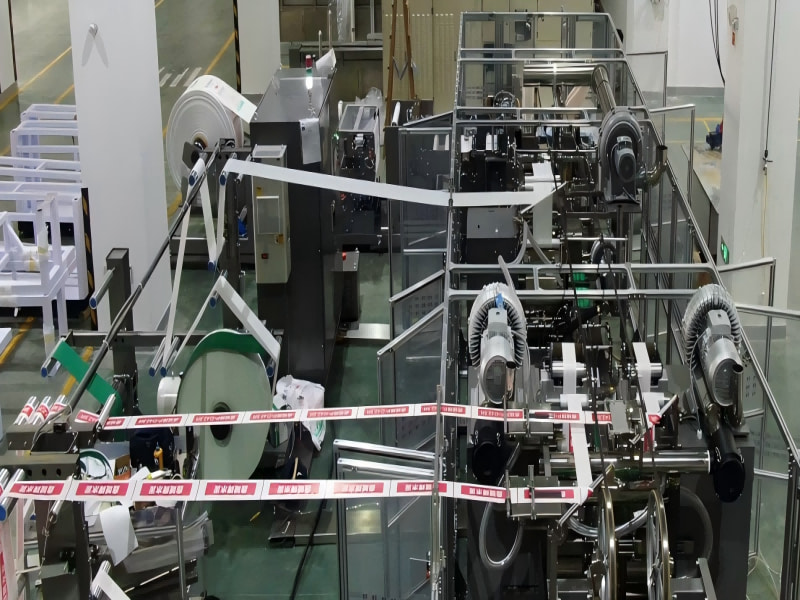

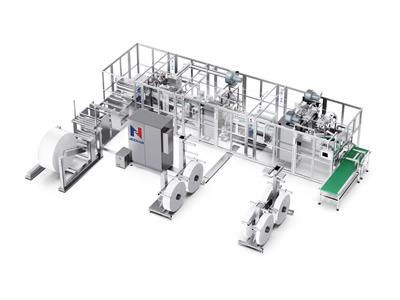

В упаковочной отрасли одностороннее ламинирование является важным инструментом для особых требований и эффективности производства в индустрии клапанов. Ламинирование-это общая технология упаковки, в которой одностороннее ламинирование достигает многих преимуществ, покрывая покрытый слой на упаковочный материал;

В настоящее время PP Woven Block Block Bag Machine Machine Whothesaler Gachn Group Clave Machine-единственное производственное оборудование на рынке, которое может производить одностороннее ламинирование и является высоко автоматизированным, гибким и стабильным, становясь идеальным выбором для упаковочной отрасли.

В фактическом производственном процессе односторонних пакетов с ламинированным клапаном, поскольку односторонние пакеты с ламинированным клапаном представляют собой только ламинирование с одной стороны, вес ламинирования меньше, чем у обычных мешков клапанов. Следовательно, температурный контроль нагревательного воздушного пистолета машины для изготовления мешка клапана является наиболее важным механизмом для производства односторонних пакетов клапанов ламинирования. Среди машин, производящих мешок для клапана на рынке, PP тканый блок Block Back Make Make Machine Поставщик поставщика Gachn Group Clap Machine - единственное оборудование, механизм теплового уплотнения, который может точно управлять сервоприводом.

Преимущества односторонних пакетов с покрытием пленки в основном отражены в следующих аспектах:

Улучшенное прикосновение и внешний вид: После односторонних пакетов клапана с покрытием пленки нить более плавные и более деликатные, внешний вид более красивый и щедрый, а общая текстура продукта может быть улучшена.

Сильная гибкость: Машина для создания клапана Gachn Group Machine может отрегулировать тип, размер и схему печати в соответствии с различными характеристиками продукта и требованиями к упаковке для удовлетворения разнообразных потребностей в упаковке.

Хорошая стабильность: Производственная клапана для обработки мешка поставщика Gachn Group Make Machine показывает хорошую стабильность и надежность в долгосрочном производстве односторонних мешков с пленкой, снижая частоту отказов и затраты на техническое обслуживание.

Энергетическая экономия и защита окружающей среды: Конструкция односторонних пакетов с покрытием пленки будет учитывать требования к экономии энергии и сокращения выбросов, использовать меньше сырья, снизить производственные затраты и уменьшить влияние на окружающую среду.

Почему машина для изготовления пакетов Gourp Gourp Gourp может производить одностороннюю пленку, покрытые мешками клапана?

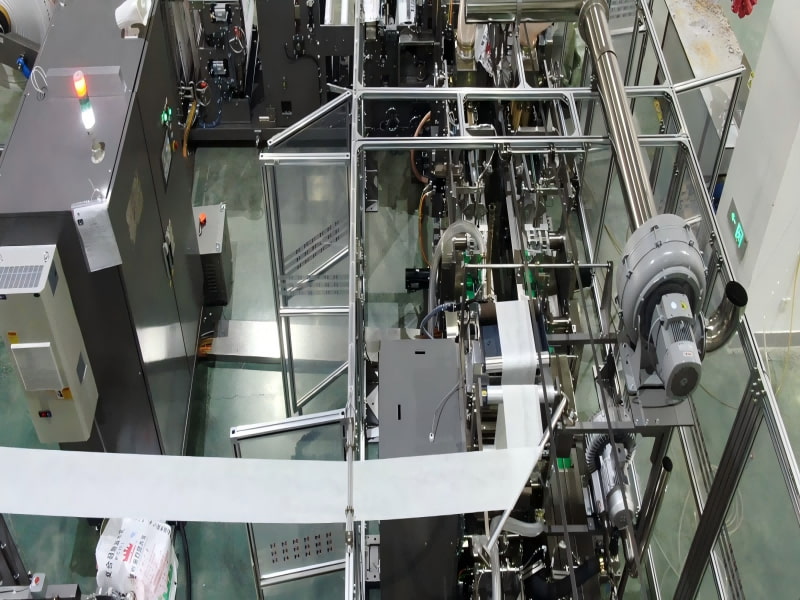

Устройство раскручивания сумки:

Машина Gourp Bag Gourp использует тяговый двигатель для управления материалом, разматывающим пассивный механизм разматывания одностороннего пакета клапана с пленкой, и оснащен магнитным порошковым тормозным устройством, чтобы гарантировать, что размахивание материала является устойчивым и надежным, а поверхность с покрытием пленки выходит в правильное направление.

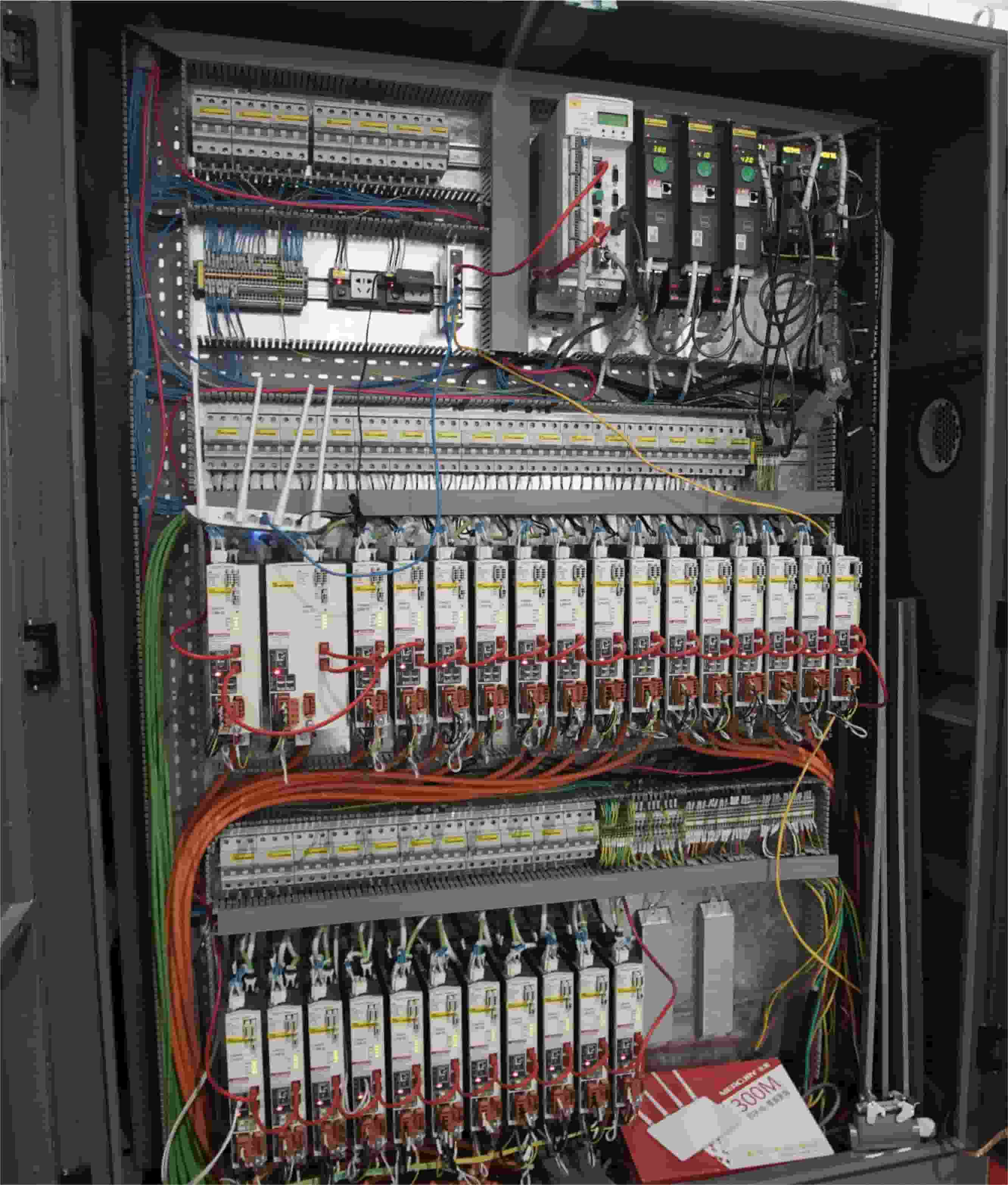

Ультра-высокий температурный нагреватель и регулируемый контроль температуры:

В одностороннем процессе покрытия пленки, сверхвысокий температурный нагревательный пистолет, оснащенный системой GACHN Gourp, может быстро достичь и поддерживать необходимую температуру сварки. Его функция регулировки температуры чрезвычайно точна, чтобы гарантировать, что нижняя наклейка не будет перегрета и герметизирована, поэтому оператор может гибко отрегулировать температуру нагрева в соответствии с характеристиками материала и сварки различных толщин, чтобы достичь наилучшего сварки одностороннего пленки. Убедитесь, что качество сварки наклейка нижней части пакета с покрытием пленки.

Обнаружение температуры термопары:

Чтобы обеспечить точное управление температурой сварки, GACHN Gourp имеет встроенное устройство обнаружения температуры термопары в системе. Это устройство может отслеживать температуру нагревательного пистолета и площадь сварки в режиме реального времени, чтобы обеспечить, чтобы процесс сварки всегда был в пределах установленного температурного диапазона, эффективно избегая проблем с качеством сварки, вызванных колебаниями температуры. Убедитесь, что односторонняя сумка с ламинированием не повредит корпус пакета

Сочетание одностороннего ламинирования с машиной для изготовления клапанов может принести большие преимущества. Во-первых, одностороннее ламинирование может снизить больше затрат на сырье, что делает его более подходящим для упаковки тяжелых или хрупких продуктов. Во-вторых, одностороннее ламинирование все еще может поддерживать внутреннее герметичность, гарантируя, что внутренние продукты не загрязнены внешним миром. Сочетая преимущества обоих, можно производить упаковочные продукты, которые являются красивыми и практичными, и повысить рыночную конкурентоспособность продуктов.

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ