Автоматическая ткани для лаковки с тканом клапаном для сумки для Adstar

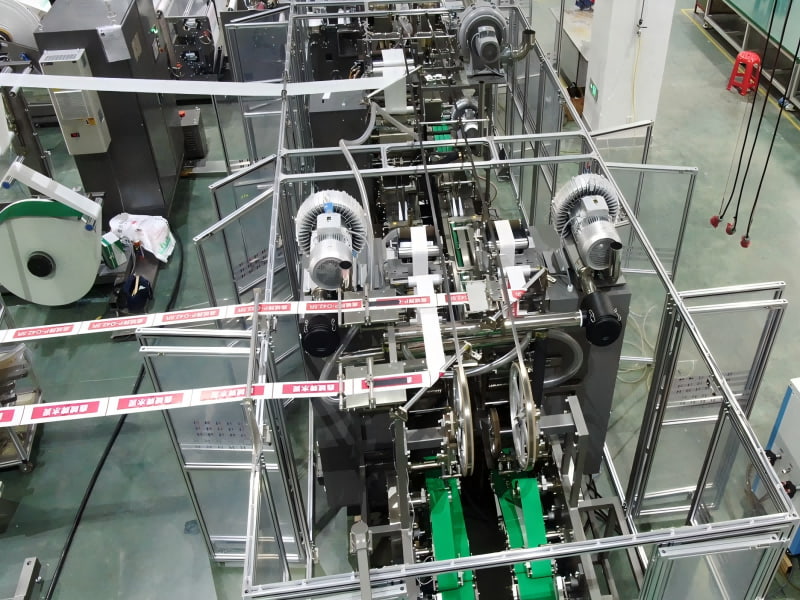

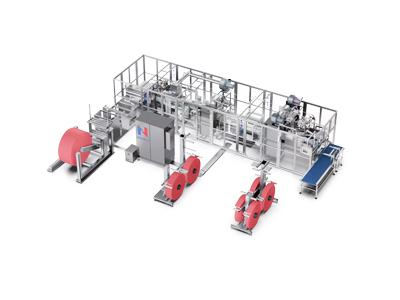

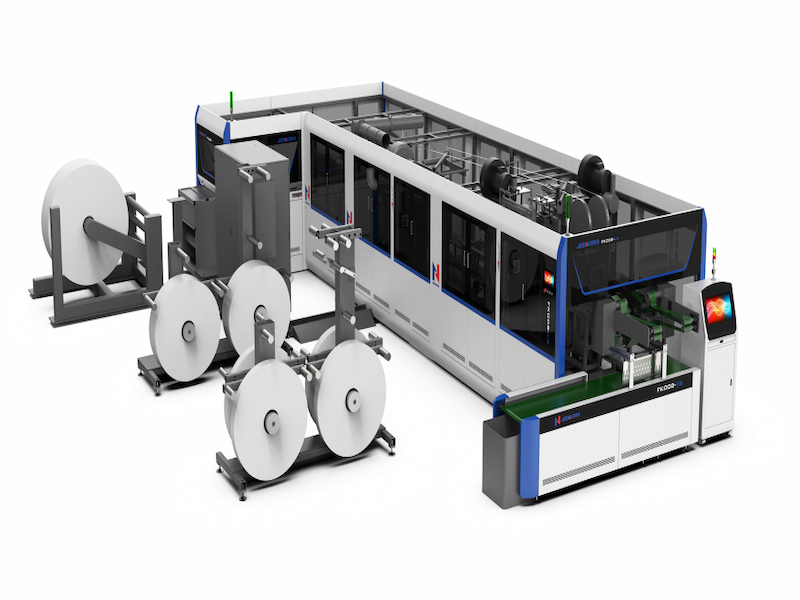

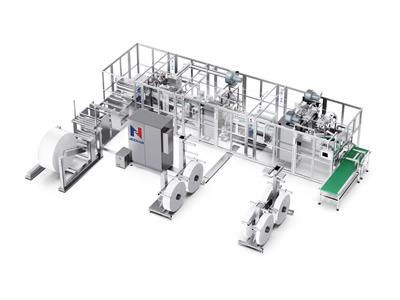

Производственная станка для обработки клапана PE клапана GACHN GOURP CANGE MANE MANE может производить мешки с клапанами различных материалов, включая PP, PE, пластический композит из бумаги и другие пакеты клапанов.

С точки зрения затрат на инвестиции: в прошлом предприятия использовали традиционное европейское оборудование для производства брендов. Производство пакета PP требует машины для изготовления мешка с клапаном PP, для производства пакета PE требуется машина для изготовления пакета PE, для производства композитных пакетов бумаги для бумаги требуется аппарат для изготовления композитной сумки бумаги, а для производства химических мешков требуется машина для изготовления химических мешков. Это производственное оборудование требует инвестиционных затрат до 1 миллиона до 2 миллионов долларов США, в то время как машина для изготовления мешков Gourp Gourp Gourp может принадлежать менее чем за 500 000 долларов США.

PE Woven Block Note Vlave Make Suctire Поставщик Gachn Gourp Clap Machine Machine может производить мешки с клапанами различных материалов с одним устройством, сэкономив клиентам миллионы долларов в стоимости оборудования. Вся машина принимает интеллектуальную систему управления с высокой эффективностью производства. Производство пакетов PE клапана может достигать 50-60PSC/мин в минуту, а производство мешков клапанов PP может достигать 140 шт./Мин. Диверсификация рыночного спроса требует, чтобы упаковочные материалы были очень настраиваемыми. Машина для пакета Gourp Gourp Gourp Cave Make может адаптироваться к потребностям изготовления мешков с различными материалами, регулируя оборудование, изменяя рулоны ткани и адаптируясь к потребностям изготовления мешков различных материалов. Эта гибкость позволяет инвесторам быстро реагировать на изменения рынка и удовлетворить персонализированные потребности клиентов, чтобы выделиться в жесткой конкуренции рынка.

Среди них пакет с пленкой PE, из-за его соотношения растяжения в 2-3 раза больше, чем у обычной пленки, и имеет большую ретракцию и длительную силу связывания, а также одностороннюю или двухстороннюю самостоятельную функцию, является пленкой со значительными преимуществами в области упаковки. Этот тип материала высоко востребована клиентами в международной химической промышленности и пользуется большим спросом в порошке и пластиковой упаковке риса.

GACHN GOURP PE VALVE SAG MARVICESTIONS

Высокое соотношение растяжения: Растяжение PE -пленочной сумки для пленки намного превышает результаты обычной пленки, что означает, что в том же месте упаковки она может более плотно обернуть и исправлять предметы и обеспечивать более сильную защиту.

Ретракция: PE Film может быстро отказаться после растяжения, тесно соответствовать упакованным предметам и эффективно предотвратить движение и столкновение предметов во время транспортировки.

Длительная сила связывания: Его длительная сила связывания может гарантировать, что элементы остаются стабильными во время долгосрочной транспортировки и уменьшают ущерб, вызванные вибрацией или ударами.

Самоклеящая функция: Односторонний или двусторонний дизайн самоклеивания позволяет этой пленке легко исправлять элементы без необходимости дополнительных инструментов или материалов для фиксации, что повышает эффективность упаковки.

Используйте преимущества

Повысить эффективность упаковки: Благодаря своей самоклеящейся функции и высоким соотношению растяжения, эта пленка может быстро и легко исправить элементы, значительно повышая эффективность упаковки.

Сокращение затрат: По сравнению с традиционными упаковочными материалами, пакеты с пленками PE могут снизить затраты на материальные отходы и затраты на рабочую силу в процессе упаковки, тем самым снижая общие затраты.

Защита окружающей среды: Как тип полиэтиленового материала, пакеты с пленками PE с пленками относительно просты в переработке и обработке, что отвечает требованиям защиты окружающей среды и устойчивости в современной упаковочной промышленности. В процессе химического производства пакеты с пленками PE не нужно разрезать, как традиционные сумки для кормления, и могут быть непосредственно включены в процесс производства.

Gachn Gourp Bag Make Machine PE Calve Bag Sack.

Почему машина для изготовления пакета Gourp Gourp Cave Make Make PE производит тепловые пакеты?

Ультра-высокая температурная нагревательная конструкция пистолета

Печата для тканого блока-нижнего клапана. Нагревательный пистолет имеет встроенную систему обнаружения температуры термопары с высокой устойчивом, которая может контролировать рабочую температуру нагревательного пистолета в режиме реального времени, чтобы обеспечить точный контроль температуры во время сварки. Это не приведет к перегреву или плохой сварке. Эта конструкция не только повышает эффективность сварки, но и эффективно гарантирует качество сварки.

Европейское оборудование: Европейское оборудование принимает механический нагревающий конструкцию воздушного оружия, которая не может контролировать рабочую температуру нагревательного пистолета в режиме реального времени, что приводит к длительному времени регулировки машины и медленной эффективности замены материала.

Устройство защиты от питания

Чтобы обеспечить безопасность и стабильность процесса сварки, Gachn Gourp специально оснащен устройством защиты от питания. В случае аномального сбоя мощности устройство может быстро реагировать, чтобы не допустить, чтобы нагревательный пистолет не мог эффективно рассеять тепло из -за остановки вентилятора, что избегает слишком высокой температуры и вызывая аварию. Этот инновационный дизайн значительно повышает стабильность и надежность сварки наклейки с наклейкой с пакетом PE клапана и эффективно снижает угрозы безопасности в производственном процессе.

Европейское оборудование: Поскольку европейское оборудование не является полной конструкцией сервопривода, в режиме реального процесса невозможно отслеживать нагревательный пистолет, что приводит к тому, что такие проблемы, как перегрев нагревательного пистолета, намного больше, чем у машины Gourp Gourp Gourp Gourp. По сравнению с машиной для изготовления мешка Gourp Gourp Gourp, она увеличивает риски производства, такие как выгорание и отключение.

Сервоконтролируемая структура переключения направления ветра рулевого вала

Gachn Gourp использует расширенную систему управления сервоприводом для управления структурой переключения направления ветра рулевого вала. Благодаря точному сервоприводу, положение сварки может быть обеспечено точным при сохранении стабильности процесса сварки клапана PE. Этот дизайн не только повышает точность сварки, но и помогает повысить общую эффективность производства и качество продукции.

Регулируемая конструкция ширины насадки

Чтобы адаптироваться к сварочным задачам различных спецификаций и требований, ширина сопла этого устройства предназначена для регулировки. Без замены каких -либо аксессуаров ширина сопла можно легко отрегулировать, чтобы удовлетворить потребности сварки различных мешков PE. Эта конструкция не только упрощает эксплуатационный процесс, но и повышает гибкость и применимость оборудования, что делает процесс сварки более эффективным и удобным.

Сумки для пленки PE имеют значительные преимущества, такие как высокое соотношение растяжения, большая ретракция, длительная сила связывания и самоклехой функции, и имеют широкие перспективы применения в областях упаковки транспорта поддонов, больших или мелких упаковок и т. Д. Это может не только повысить эффективность упаковки и снизить затраты, но и удовлетворять требованиям современной индустрии упаковки для защиты окружающей среды и устойчивости и устойчивости и является центром центров индустрии пластической индустрии.

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ