Высококачественный автоматизированный погрузчик грузовиков использует прочную механическую конструкцию в качестве своих «конечностей», но его истинная душа кроется в его «глазах» и «мозге». На этой неделе мы углубимся в суть и расскажем, как погрузчик грузовиков Gachn обеспечивает высокоинтеллектуальную, беспилотную загрузку благодаря эффективному взаимодействию 3D-зрения, алгоритмов искусственного интеллекта и передовых систем управления.

За последние две недели мы обсудили болевые точки отрасли и представили революционное механическое решение для «входа в грузовой отсек». Однако для того, чтобы роботизированная рука точно выдвигалась в кузов грузовика и идеально укладывала грузы, необходима интеллектуальная система восприятия, принятия решений и исполнения. Именно это отличает Gachn от простого автоматизированного оборудования, представленного на рынке, делая его по-настоящему «умным погрузчиком».

I. Умные глаза: всестороннее восприятие для четкой идентификации транспортного средства

Основная технология: Система 3D-сканирования LiDAR и интеллектуального определения местоположения транспортного средства

Проблемы:Огромные различия в парковке транспортных средств: неправильная парковка, отклонение от осевой линии и посторонние предметы в грузовом отсеке (например, остатки крепежных тросов или мусор) могут привести к сбоям при погрузке или даже к столкновениям оборудования.

Наше решение:

Точное моделирование: Оборудование использует высокоточный лидар для кругового сканирования припаркованного автомобиля, создавая трёхмерную модель облака точек с точностью до миллиметра. Система автоматически измеряет длину, ширину и высоту боковой панели грузового отсека, а также дорожный просвет автомобиля.

Разумное суждение: Используя разработанный компанией интеллектуальный алгоритм обнаружения, система анализирует данные облака точек в режиме реального времени. Она автоматически определяет, находится ли транспортное средство в пределах разрешенной зоны автоматической погрузки и находится ли отклонение осевой линии в контролируемом диапазоне. Одновременно система выполняет функцию «контролера качества», выявляя любые неровности в грузовом отсеке, предотвращая неустойчивое штабелирование или неисправности оборудования, вызванные посторонними предметами.

Активное руководство: Если система обнаружит, что задняя панель расположена слишком высоко или положение парковки неправильное, она заблаговременно напомнит водителю на экране о необходимости «открыть заднюю панель» или «отрегулировать положение парковки», обеспечивая взаимодействие человека и машины и идеальную отправную точку для операции.

(Видео: демонстрирует 3D-модель облака точек транспортного средства, созданную после сканирования LiDAR, с отмеченными измеренными размерами длины, ширины и высоты)

II. Интеллектуальный мозг: стратегическое планирование оптимального пути загрузки

Основная технология: Запатентованный алгоритм паллетирования и высокопроизводительная платформа управления Schneider Electric

Испытание:Как преобразовать известные габариты транспортного средства и тоннаж, подлежащий загрузке, в точные, аккуратные и стабильные координаты паллетирования и траектории движения для каждого мешка цемента?

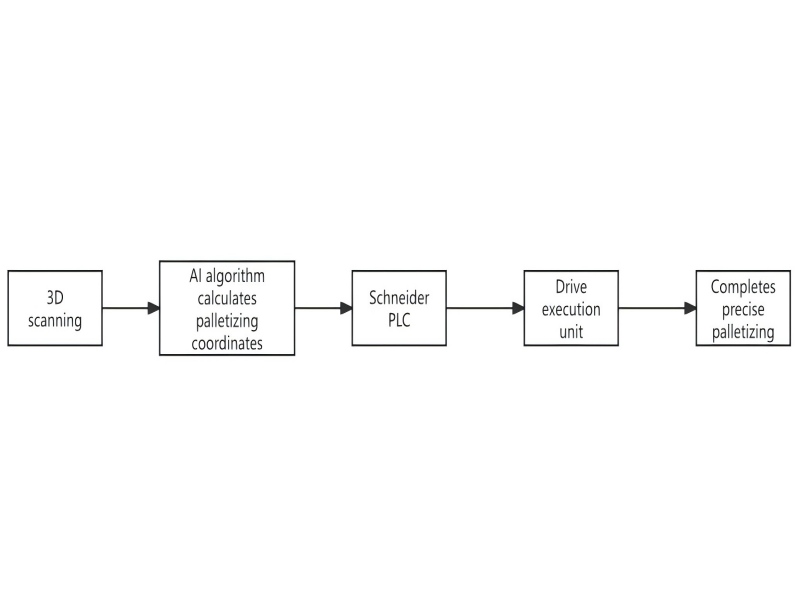

Наше решение:Интеллектуальный расчёт: после получения данных 3D-сканирования начинает работу наш самостоятельно разработанный алгоритм паллетирования. На основе тоннажа загружаемого цемента и математической модели он автоматически рассчитывает оптимальные координаты посадки для каждого мешка цемента и планирует наиболее эффективную траекторию движения без столкновений.

Гибкая стратегия: Алгоритм поддерживает три режима: горизонтальное и вертикальное штабелирование, а также их комбинацию. Он может интеллектуально выбирать или комбинировать режимы в зависимости от размеров кузова, обеспечивая плотное и аккуратное штабелирование, максимально эффективное использование пространства кузова и упрощая разгрузку.

Точное исполнение:Рассчитанные инструкции по траектории принимаются и исполняются системой управления, основанной на высокопроизводительном 12-осевом контроллере движения Schneider и большом 15,6-дюймовом сенсорном экране. Стабильность и высокая вычислительная мощность ПЛК Schneider обеспечивают синхронизацию, точность и надежность работы всех серводвигателей, цилиндров и других исполнительных механизмов.

III. Нейронные сети: взаимодействие данных, обеспечивающее интеллектуальное управление производством

Основная технология: Система управления загрузочной информацией и промышленный интерфейс

Испытание: Автоматизированная загрузочная машина не должна быть хранилищем информации; она должна органично интегрироваться с существующей системой управления завода.

Наше решение: Водителю нужно лишь провести своей картой рядом с погрузочной машиной, и система автоматически извлечет информацию о вывозе (такую как клиент, тип продукта и тоннаж) из ERP-системы, устраняя необходимость ручного ввода и предотвращая ошибки.

После завершения загрузки данные (такие как фактическое время погрузки и тоннаж) автоматически передаются обратно в систему управления, образуя замкнутый цикл и обеспечивая точную информационную поддержку в режиме реального времени для финансовых расчетов и планирования производства.

Оборудование в стандартной комплектации оснащено интерфейсом Ethernet, что обеспечивает достаточно места для расширения возможностей завода в рамках будущих модернизаций по стандартам «Индустрия 4.0» и «умного» производства.

IV. Надежная основа: распределенная компоновка и компоненты верхнего уровня

Мы понимаем, что даже самая интеллектуальная система требует стабильной аппаратной поддержки. В отличие от конкурентов, которые централизуют субподрядные, управляющие и упаковочные механизмы, что приводит к «небольшому пространству для обслуживания и сложному устранению неисправностей», Gachn использует распределённую компоновку. Такая компоновка не только обеспечивает более высокую стабильность, но и предоставляет широкий доступ для обслуживания при необходимости, что позволяет быстро локализовать и устранить проблемы, значительно сокращая время простоя и повышая общую эффективность оборудования (OEE).

Заключение: Настоящий интеллект — это идеальная интеграция восприятия, принятия решений, исполнения и управления. Погрузочная машина Gachn — именно такой интеллектуальный эксперт по погрузке с «орлиным зрением», «супермозгом» и «гибкими конечностями». Она обеспечивает не только экономию рабочей силы, но и существенный скачок в качестве погрузки, эффективности управления и прозрачности данных.

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ

IPv6 ПОДДЕРЖИВАЕМАЯ СЕТЬ